MIL-DTL-83526C

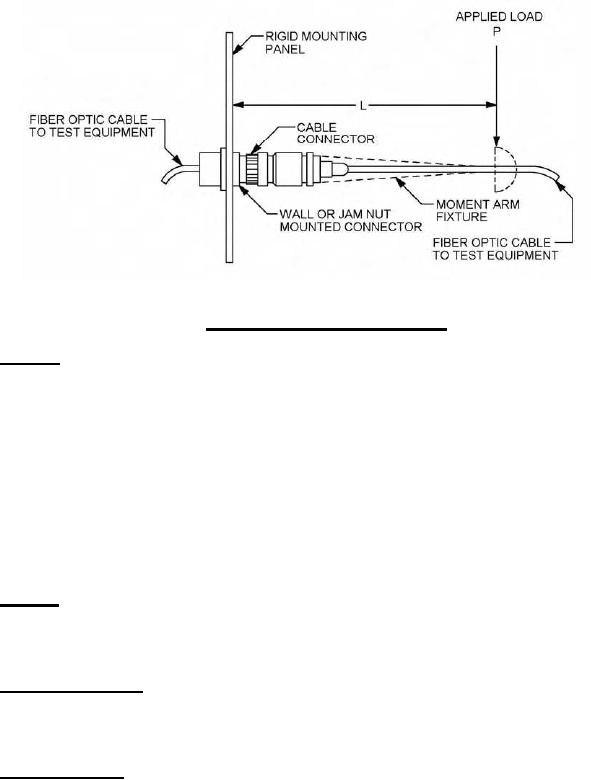

NOTE: Moment arm fixture shall be of a convenient design.

FIGURE 1. External bending moment test setup.

4.9.23 Vibration. A complete connector assembly shall be mounted as shown on figure 2 or suitable

test fixture and vibrated in accordance with EIA/TIA-455-11 as follows; test conditions III at 10 G's and

test condition VI, test letter C for 1.5 hours. Specimen cable, using the normal connecting devices of the

connector and clamped as shown on figure 2, shall be used. The connector shall be mounted by its

normal mounting device. Cable to cable connectors may be held to the jig of figure 2 by a suitable clamp

on one half of the connector assembly. The following conditions shall apply:

a. Test condition letter if other than above (see 3.1).

vibration.

c. Upon completion of the test, the connectors shall be examined for compliance to 3.11.23.

4.9.24 Humidity. Cable-connected assemblies (at least one mated and one unmated), shall be tested

in accordance with test method B of TIA/EIA-455-5 for 10 total cycles with 5 including sub cycle. The

cable used shall be in accordance with MIL-PRF-85045. Measurements shall be made of the sample

after conditioning process and after humidity test (see 3.11.24).

4.9.25 Salt spray (corrosion). Mated cable-connector assemblies shall be tested in accordance with

test condition I of TIA/EIA-455-16. After test exposure, the assemblies shall be externally cleaned and

examined under 3 power magnification for salt penetration into the connector junction area and damage

to external parts (see 3.11.25).

4.9.26 Altitude immersion. Mated connectors shall be tested in accordance with TIA-455-15. Cables

25

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business