MIL-DTL-83526C

Inches

mm

.12

3.1

.25

6.4

3.50

88.9

4.25

107.9

8.00

203.2

NOTES:

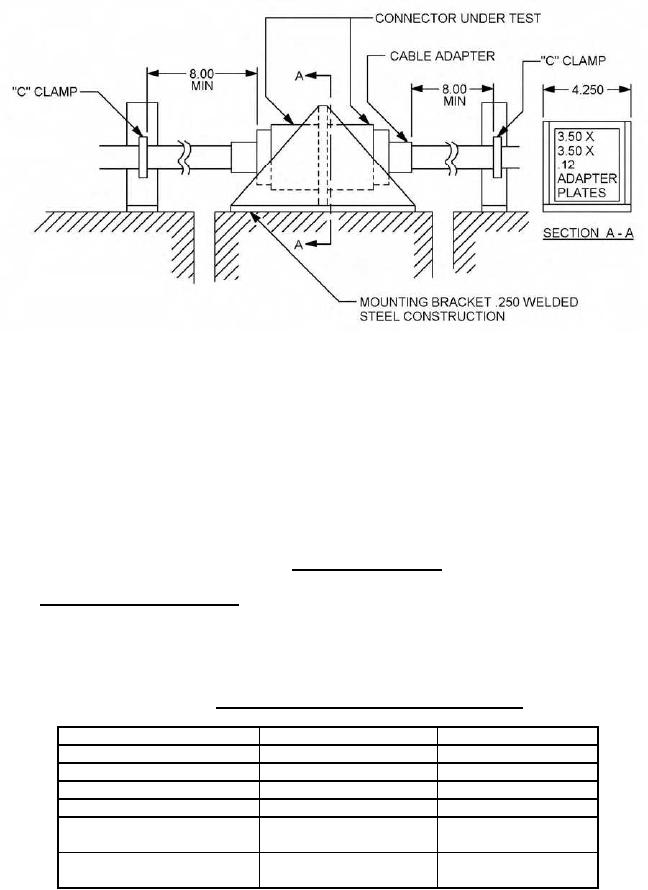

1. Dimensions are in inches.

2. Metric equivalents are given for general information only.

3. Dimensions and tolerances are in accordance with ASME Y14.5M.

FIGURE 2. Vibration testing setup.

4.9.27 Fluid immersion (see 3.11.27). At least one mated cable-connector assembly shall be tested in

accordance with EIA/TIA-455-12. Assemblies shall be immersed in each of the fluids listed in table VIII at

the temperature specified for 24 hours. Each assembly shall be completely dried after each immersion.

After testing, the assemblies shall be examined for fluid penetration into the shell body and connector

junction region. Instead of optical transmittance, insertion loss shall be measured after the test (see

3.10.1).

TABLE VIII. Fluids and test temperature for immersion test.

Fluid

Applicable specification

Test temperature (ºC)

Fuel oil

MIL-PRF-16884

33 to 37

Turbine fuel, JP-4

MIL-DTL-5624

20 to 25

Isopropyl alcohol

TT-I-735 (see 6.9)

20 to 25

Hydraulic fluid

MIL-PRF-5606 (see 6.5)

48 to 50

Lubricating oil

MIL-PRF-17331

73 to 77

MIL-PRF-23699

73 to 77

Coolant Fluid, Hydrolytically

MIL-PRF-87252

20 to 25

Stable, Dielectric

26

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business