MIL-DTL-83526C

4.7.1.2.3 Disposition of sample units. Sample units that have failed any of the group A inspection tests

may be reworked to correct defects if possible and subjected to group A inspection again. Sample units

that pass all tests of group A inspection may be delivered on the purchase order or contract or tested to

group B inspection (see 4.7.1.3). Units that have not been corrected shall not be delivered on any order

even though the inspection lot submitted is accepted.

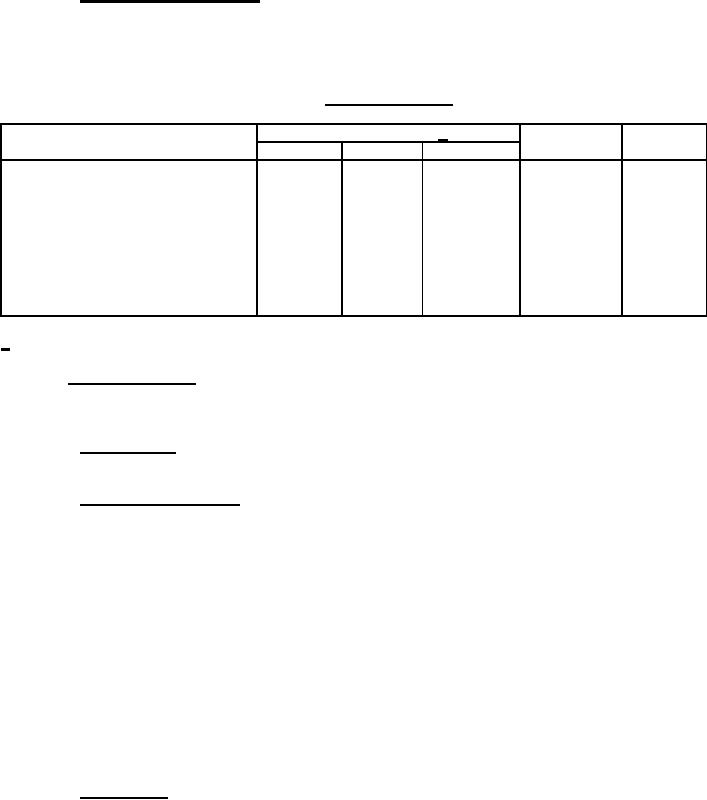

TABLE IV. Group A inspection.

Part applicability 1/

Inspection

Requirement

Test

paragraph

paragraph

Connector Backshell Accessories

Workmanship

X

X

X

Size

X

X

X

Weight

X

X

X

Color

X

X

X

Identification marking

X

X

Terminus insertion and removal

force

X

Coupling forces

X

X

X

Coupling torques

X

X

X

1/ X: Indicates that this test applies.

4.7.1.3 Group B inspection. Group B inspection shall consist of the inspections and optical tests

specified in table V, in the order shown, and shall be made on sample units which have been subjected to

and have passed the group A inspection.

4.7.1.3.1 Sampling plan. Samples shall be selected at random from the inspection lot. Sample size

shall be in accordance with table III. If one or more defects are found, the lot shall be rejected.

4.7.1.3.2 Sample unit preparation. Connectors shall be fully assembled into cable-connector

assemblies using the types of cable specified in MIL-PRF-85045. In case of no qualified sources, the

following cable or equivalent shall be used.

2 Channel

PIN M85045/8-B2B, 50 micron core, 125 clad, or equal.

4 Channel

PIN M85045/8-B4B, 50 micron core, 125 clad, or equal.

2 Channel

PIN M85045/8-B2A, 62.5 micron core, 125 clad, or equal

4 Channel

PIN M85045/8-B4A, 62.5 micron core, 125 clad or equal

Connector terminals shall be optically finished with termini properly seated within their inserts. For mated

connectors, full sealing capability shall be provided as specified (see 3.1). Connectors shall be provided

with backshell, strain relief cable clamp and attached to a six feet length of the specified cable type, and

shall be terminated in accordance with the manufacturer's instructions.

4.7.1.3.3 Rejected lots. If an inspection lot is rejected, the contractor may rework the lot to correct the

defects or screen out the defective units and resubmit for reinspection. Resubmitted lots shall be

inspected using the sample size of the next higher lot size specified in table III. Such lots shall be

separate from new lots and shall be clearly identified as reinspected lots.

18

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business