MIL-DTL-83526C

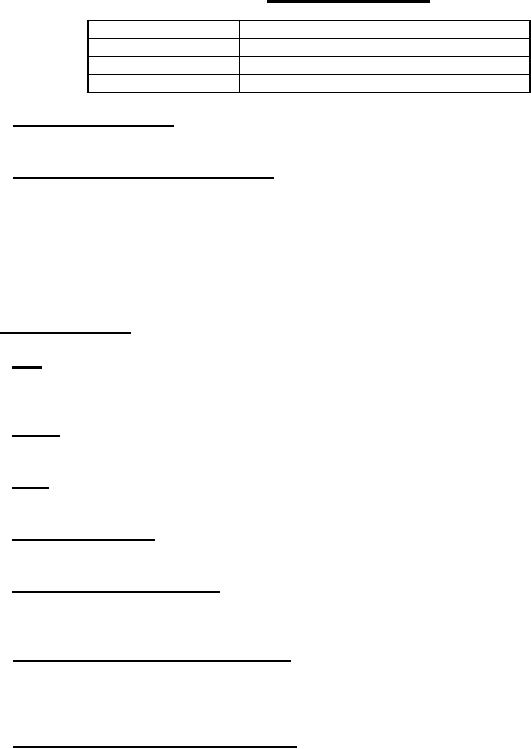

TABLE VII. Measurement frequency.

Test duration (hrs.)

Time(s) after start of test (hrs.)

4 and less

Half way through

More than 4 to 6

1/3 and 2/3 of the way through the test

More than 6

¼, ½, and ¾ of the way through the test

4.8.6 Return loss (see 3.10.6). The return loss shall be measured in accordance with

TIA/EIA-455-107.

4.8.7 Ambient light susceptibility (see 3.10.7). The optical connector shall be tested in accordance

with TIA-455-22. The optical termini of the connector shall be either opaquely capped or connected to a

minimum of 4 meters of optical test cables as appropriate. The far ends of these cables shall be either

capped or connected to suitable optical power monitoring instruments. The light shall be broad spectrum

with infrared, visible, and ultraviolet components and shall illuminate the connector with an irradiance

(power density) of 112 ±5 milliwatts per square centimeter. Light emitting from each optical part of the

device under test shall be measured by optical power monitoring equipment, having a broad spectral

response compatible with the source.

4.9 Inspection methods.

4.9.1 Size. Each of the dimensions specified (see 3.1) for the connector, backshell, and accessory

parts shall be measured using calibrated measuring devices with the precision and accuracy appropriate

4.9.2 Weight. The connector, backshell and accessories shall be weighed using calibrated scales

having the range, precision and accuracy appropriate for the tolerances specified (see 3.1 and 3.11.2).

4.9.3 Color. The colors of connectors, backshells, and accessories shall be nonreflective (see

3.11.3).

4.9.4 Identification marking. Identification markings on connectors, backshells and accessory parts

shall be visually examined and measured for conformance with the requirements of 3.11.4.

4.9.5 Terminus cleaning (see 3.11.5). The optical face of each terminus shall be cleaned according to

the instructions supplied by the connector manufacturer. The terminus shall not be removed from its

operational position within the connector to facilitate cleaning.

4.9.6 Insert retention axial strength (see 3.11.6). Unmated connector samples shall be tested as

follows. The pressure shall be applied as specified (see 3.11.6) and the axial displacement measured

(see 3.11.6). The same pressure shall then be applied on the opposite face. Termini positions within the

insert may be either empty or filled during the test.

4.9.7 Insert retention radial strength (see 3.11.7). Unmated connector samples shall be tested where

specified (see 3.1), for radial strength as described herein. Counterpart test devices for connector shall

be supplied by the connector manufacturer, which are capable of applying radial torque forces between

the insert and its shell body. Outermost termini positions or other means may be used for application of

these torques, however, no damage shall occur to the insert as a result of the test exposure. A radial

torque shall be applied as specified (see 3.1).

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business