MIL-DTL-83526C

e) Protective covers and storage receptacles meet the requirements of 3.7 and the appropriate

specification sheet (see 3.1).

f) Cable strength member terminations meet the requirements of 3.8 and the appropriate

specification sheet (see 3.1).

h) Assembly instructions are included as required by 3.12 and the appropriate specification sheet

(see 3.1).

potter's clay and sharp sand mixed with water (10% by weight) shall be contained in a vessel to a depth

of 5 inches minimum. Two in-line connectors shall be mated and the insertion loss recorded in

accordance with TIA-455-20. Decouple and immerse both connectors in the mud bath for 5 minutes

minimum. Remove the connectors and clean with water (immersion in the water is allowed). Connectors

may be cleaned and dried. Removal of the insert cap for termini cleaning is allowed, but further

disassembly of the connectors during cleaning is not allowed. Re-mate and record the received signal

using TIA-455-20. Insertion loss measured per 4.8.1 shall not exceed the limit specified in 3.14. Repeat

the above test for a total of 10 times.

4.11 Fungus resistance (see 3.3.4.6). Connector materials not listed as fungus inert in guideline 4 of

MIL-HDBK-454 (see 6.10) shall be tested in accordance with TIA/EIA-455-56 for a duration of 28 days.

4.12 Electromagnetic shielding. Electromagnetic shielding testing of receptacles mated to plugs with

backshells and of receptacles mated to dust covers shall be conducted as follows. The test specimens

(including terminated cable) shall be tested to determine the propagation characteristics (attenuation or

conduction) of the specimen assembly. The shielding effectiveness of a shielded enclosure shall be

verified in accordance with the procedures specified in IEEE-299 at the discrete frequencies specified in

Table IX with the test specimen mounted in position. The test specimen receptacle shall be mounted into

the wall (panel) of the shielded enclosure such that the plug or dust cover mates from the inside of the

shielded enclosure. The cable(s) from the plug and receptacle shall be extended parallel to the test

specimen for a minimum of 2 m on each side of the enclosure wall (panel). The dynamic range of the test

setup shall be measured as specified in IEEE-299 at each discrete frequency specified in table XI. The

measured level of radio frequency (RF) propagation through the test specimen installed in the shielded

enclosure shall be determined in accordance with the procedures specified in IEEE-299 at each discrete

frequency specified in table XI.

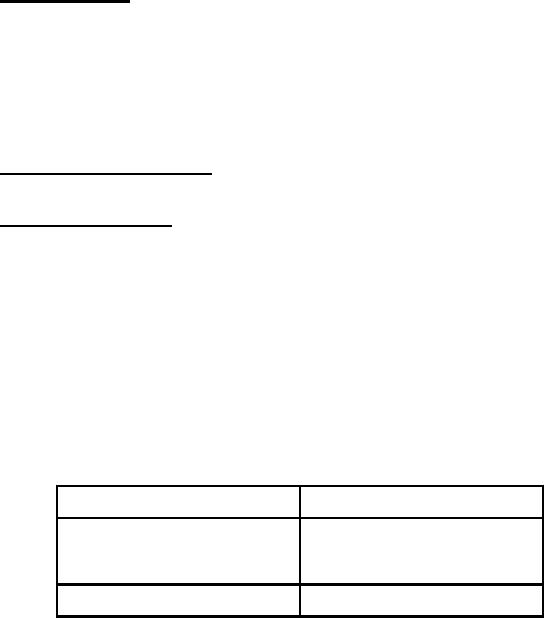

Table IX. Electromagnetic effects test frequencies.

Field propagation

Test frequencies

100 MHz

Planewave

400 MHz

1 GHz

Microwave

10 GHz

28

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business