MIL-PRF-29504/4D

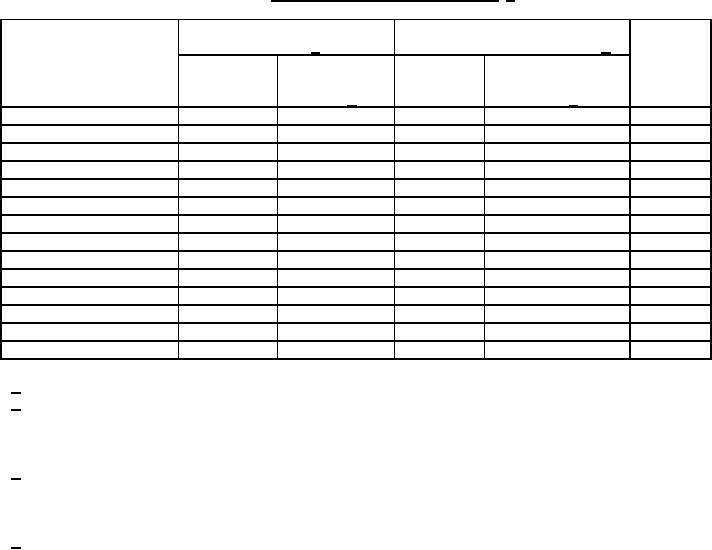

TABLE IV. Optical insertion loss performance. 1/

Termini in non-tight tolerance

Termini in tight tolerance

M38999 2/

M38999/60 and M38999/61 3/

Ferrule

Fiber

Initial

Insertion

Initial

Insertion loss

material

size

insertion

loss verification

insertion

verification

(dB) 4/

loss (dB)

(dB) 4/

(um)

loss (dB)

Single mode < 9/125

1.25

1.75

1.25

1.75

Ceramic

Single mode 9/125

0.75

1.25

0.75

1.25

Ceramic

50/125

1.50

2.00

1.00

1.50

Ceramic

62.5/125

1.00

1.50

0.75

1.25

Ceramic

62.5/125/polyimide

1.50

2.00

1.00

1.50

Ceramic

100/140

0.75

1.25

0.75

1.25

Ceramic

100/140/polyimide

1.50

2.00

1.00

1.50

Ceramic

> 100/140

1.50

2.00

1.25

1.75

Ceramic

50/125

1.50

2.00

1.25

1.75

Metal

62.5/125

1.25

1.75

1.00

1.50

Metal

62.5/125/polyimide

1.50

2.00

1.25

1.75

Metal

100/140

1.25

2.25

1.00

1.50

Metal

100/140/polyimide

1.50

2.50

1.00

1.75

Metal

200/230

1.50

2.50

1.00

1.75

Metal

1/ Optical loss performance is based on use of specified fabrication procedure.

2/ Termini in a MIL-DTL-38999 connector that is other than MIL-DTL-38999 tight tolerance series III

connector (the latter being built to specification sheets MIL-DTL-38999/60 and MIL-DTL-38999/61

specific to fiber optic applications), the former distinguished from the tight tolerance type by denoting

as the MIL-DTL-38999 non-tight tolerance connector.

3/ Termini in a MIL-DTL-38999 tight tolerance series III connector (the MIL-DTL-38999/60 and MIL-DTL-

38999/61 specific to fiber optic applications) for shell sizes 9 through 19. For shell sizes 21 through

25, use performance requirements when termini are used in a MIL-DTL-38999 non-tight tolerance

connector.

4/ Insertion loss verification is an insertion loss performed after a series of environmental tests or

mechanical tests.

Mechanical. The following mechanical tests shall be performed in the sequence listed following the

post mating durability, terminus cleaning and return loss tests, mechanical shock and vibration. For

single mode termini, a discontinuity is considered to be a reduction of optical transmittance of 0.5 dB

or more for a duration of 50 microseconds or more (during vibration) or 100 milliseconds or more

(during shock).

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business