MIL-PRF-29504/4D

Cable strain relief capture mechanism. Three styles for a capture mechanism are specified for this

terminus design (see table I). Cable strain relief capture mechanism shall not interfere with intended

sealing performance of wire grommet seal, a component in the MIL-DTL-38999 connector, or with

the functionality of the insertion and removal tools (see table II).

Style 1: Captive strength member outside barrel (body) with shrink sleeve.

Style 2: Captive strength member inside terminus barrel (body).

Style 3: Captive strength member outside terminus barrel (body) with crimp sleeve. The

terminus shall meet all the requirements when the crimp sleeve is assembled to the terminus

using a crimp die with flats measuring .088 ± .001 in (2.235 ± .025 mm) across and .150 inch

(3.81 mm) maximum long. The crimp die shall not contain an optional protrusion on either upper

or lower die.

Tools: See table II.

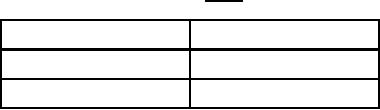

TABLE II. Tools.

Tool

PIN

Insertion tool

M81969/14-03

Removal tool

M81969/14-03

Mating terminus: MIL-PRF-29504/5.

Circular run-out: Not greater than the value specified in table I.

Frequency of terminus end face cleaning. Unless otherwise specified, terminus may be cleaned

before or after each test if the connector is demated. Cleaning shall not be performed during the ten

successive mates for the insertion loss test. Unless otherwise specified, cleaning may be performed

during mating durability before each optical transmittance measurement. Terminus end face

cleaning shall be performed for the post optical transmittance measurement after the salt spray test.

The optical transmittance measurement is performed after the general cleaning and inspection for

corrosion. Cleaning may be performed at other times when degradation in optical performance

occurs. Cleaning performed as a corrective action for degraded optical performance shall be noted

on the data sheet. Unless otherwise specified, cleaning of the optical end faces is to occur without

removal of termini from the connector.

Qualification inspection. Inspections and sequence shall be performed as listed in table III.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business