MIL-PRF-24623C

3.6.6 Ambient light susceptibility. When tested in accordance with 4.7.3.6, the

optical power of the light from the fibers (after accounting for cable losses and

optical junction losses between the fiber and the detector) shall be less than -50 dBm

(dB ref. to 1 mw).

Environmental requirements.

3.7

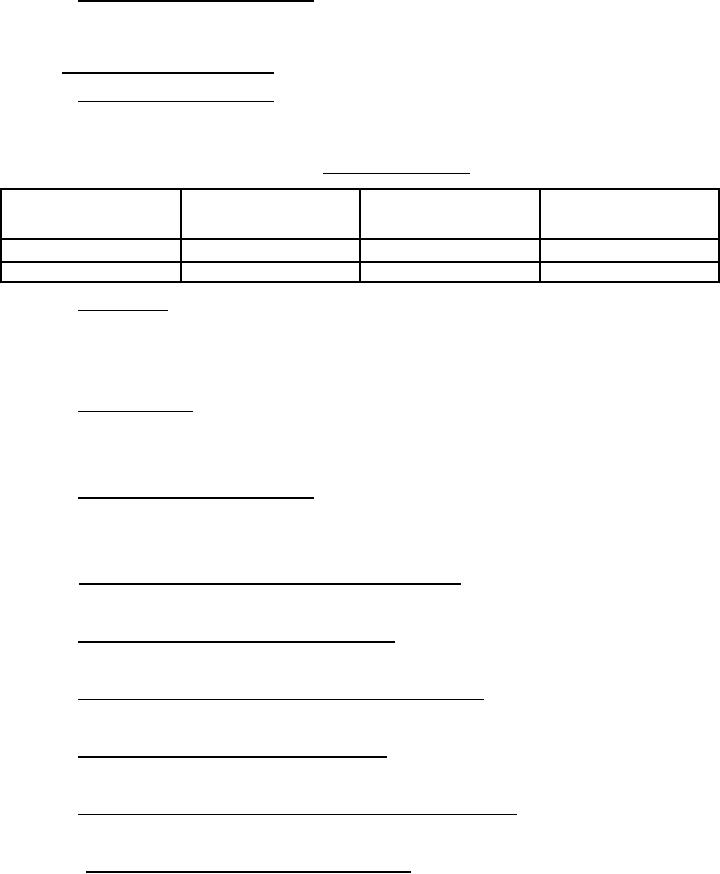

3.7.1 Environmental properties. The splice shall meet all the specified

requirements (see 3.1), during the specified operating environments and after the

specified storage environments. The operating and storage temperature ranges shall be

as specified (see 3.1) in table I.

Temperature ranges.

TABLE I.

Range

Operating

Storage temperature

Non-operating

(oC)

temperature

temperature (oC)

(oC)

1

- 46 to +85

-54 to +85

-62 to +85

2

-55 to +125

-55 to +125

-65 to +200

3.7.2 Life aging. When tested in accordance with 4.7.4.1, the splices subjected to

these specified accelerated aging exposures shall not exhibit visual evidence of

dimensional change, opening of seals, cracking or crazing of components or finishes,

identification marking impairment, leakage of waterproofing compounds or other defects

detrimental to their operation. The splice shall meet the requirements of 3.6.2 after

the test.

3.7.3 Thermal shock. When tested in accordance with 4.7.4.2, a post test visual

examination of the test splices shall reveal no leakage of waterproofing compounds or

other apparent loss of sealing capability, no surface or identification marking

impairment, nor any damage detrimental to the operation of the splice. The splice

shall meet the requirements of 3.6.2 after the test.

3.7.4 Temperature/humidity cycling. When tested to high humidity and cyclic

temperature exposures in accordance with 4.7.4.3, the splice parts shall not swell,

neither shall they have impaired identification markings, nor shall they degrade such

that splice performance is impaired. The splice shall meet the requirements of 3.6.2

during and after the test.

3.7.5 Salt spray (corrosion) (for cable splice only). When tested in accordance

with 4.7.4.4, no visible evidence of salt penetration into splice enclosures shall be

observed and no corrosive effects shall be seen on the external splice parts.

3.7.6 Water pressure (for cable splice only). When tested in accordance with

4.7.4.5., visual inspection of the test splice shall reveal no penetration of water

into the sealed region of the splice.

3.7.7 Freezing water immersion (for cable splices only). When tested in accordance

with 4.7.4.6, the splices shall not be damaged during exposure. The splices shall

meet the optical requirements of 3.6.2 during and after the test.

3.7.8 Sand and dust (for cable splice only). When tested in accordance with

4.7.4.7, the splices shall not be damaged during exposure. The splices shall meet the

optical requirements of 3.6.2 during and after the test.

3.7.9 Nuclear radiation resistance (for lensed splice only). When tested in

accordance with 4.7.4.8, the splices shall not be damaged during exposure. The

performance requirements of 3.6.2 shall be met during and after the test.

3.7.10 Fluid immersion (for cable splice only). When tested in accordance with

4.7.4.9, visual examination of the splice shall reveal no swelling or softening of

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business