MIL-PRF-24623C

TABLE V.

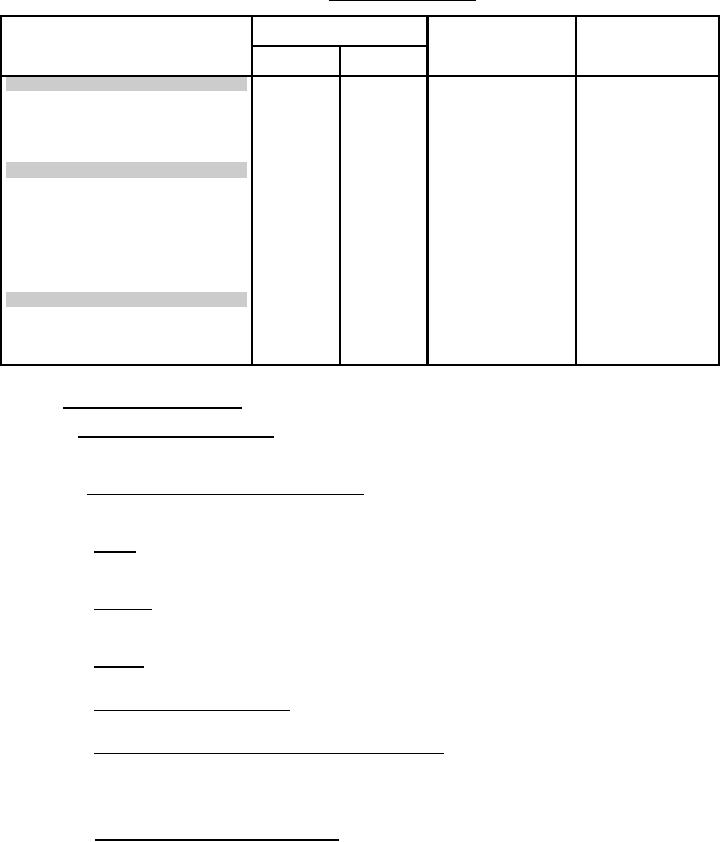

Group C inspection.

Inspection

Application

Requirement

Test method

paragraph

paragraph

Cable

Fiber

splice

splice

Group I (all sample units)

Optical

X

X

3.6.1

4.7.3.1

Insertion loss

X

X

3.6.3

4.7.3.3

Return loss

X

3.6.5

4.7.3.5

Crosstalk

Group II (4 sample units)

X

3.5.13

4.7.2.13

Cable pull out

X

3.5.12

4.7.2.12

Fiber pull out

X

3.5.7

4.7.2.7

Axial compressive loading

X

3.5.6

4.7.2.6

Twist

X

X

3.5.9

4.7.2.9

Impact

X

3.5.8

4.7.2.8

Crush

X

X

3.5.11

4.7.2.11

Mechanical shock

Group III (4 sample units)

Temperature/humidity cycling

X

X

3.7.4

4.7.4.3

Temperature cycling

X

X

3.7.12

4.7.4.11

Life aging

X

X

3.7.2

4.7.4.1

Insertion loss

X

X

3.6.1

4.7.3.1

4.7

Methods of inspection.

4.7.1 Equivalent test methods. The use of equivalent test methods is allowed

provided the preparing activity and the qualifying activity have approved the use of

that equivalent test method by that manufacturer (see 6.3.4).

Visual and mechanical examination. The splice and splice parts shall be

4.7.2

examined to verify that materials, design, construction, physical dimensions, marking,

and workmanship are in accordance with the applicable requirements (see 3.3 and 3.4).

4.7.2.1 Size. Each dimension identified in the specification sheet (see 3.1) for

the splice parts shall be measured using calibrated measuring devices with the range,

precision and accuracy appropriate for the tolerances specified (see 3.5.1).

4.7.2.2 Weight. The splice or splice parts shall be weighed using calibrated scales

having the range, precision and accuracy appropriate for the tolerances specified (see

3.5.2).

4.7.2.3 Color. The color of the splice or splice parts shall be visually inspected

for compliance, as specified in the specification sheets (see 3.5.3).

4.7.2.4 Identification markings. Identification markings on the splice parts shall

be visually examined and measured for conformance with the requirements of 3.5.4.

4.7.2.5 Cable seal flexing (for cable splice only). The splice shall be tested in

accordance with TIA/EIA-455-1. After test exposure, the assemblies shall be visually

examined for seal damage. The cable splice assembly shall be exposed to 100 flexing

cycles, the assembly rotated approximately 90O in the flexing fixture and then exposed

to another 100 flexing cycles (see 3.5.5).

4.7.2.6 Twist (for cable splice only). The splice shall be tested in accordance

with TIA/EIA-455-36, for 50 cycles. The tensile load shall be 5 newtons and the

number of loads to be applied shall be one (see 3.5.6). The change in optical

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business