MIL-PRF-24623C

transmittance shall be measured during and after the test (see 4.7.3.2). Change in

optical transmittance measurements shall be made after the 10th, 25th, and 50th cycle.

At the completion of the test, the splice shall be visually examined in accordance

with 4.7.2.

4.7.2.7 Axial compressive loading (for cable splice only). Axial compressive

loading shall be tested as specified herein. If the two ends of the splice assembly

are essentially identical, only one end of each splice assembly need be tested (see

3.5.7).

a. The test cable forming a part of the assembled splice shall be gripped over a

length equal to at least three cable diameters, starting one cable diameter

from the splice enclosure or the strain relief if it is external to the

enclosure. The splice enclosure shall be gripped so as not to alter any of its

mechanical properties.

The gripped cable and splice enclosure shall be forced together along the

b.

direction of the cable axis where the cable enters the splice assembly. The

force magnitude is a function of the cable diameter as listed in table VI.

Loading and unloading rates are such that the splice is compressively loaded

and unloaded linearly in time, with the loading and unloading times each less

than 10 seconds. The time spent under full compressive load shall be at least

1 minute. No tensile load shall be applied.

c. Any suitable test fixture may be used provided it properly grips the splice

enclosure and cable, allows control and measurement of the applied compressive

axial force, and allows visual observation of the region where the cable meets

the splice assembly. The test fixture must also allow for the performance of

any optical tests called for while the splice assembly is subject to the

compressive axial load.

d. With load applied, measure the distance between the fixture clamp and the

enclosure or strain relief and measure the insertion loss.

e. Remove the load.

f. Visual observations and examinations shall be made with 3X magnification.

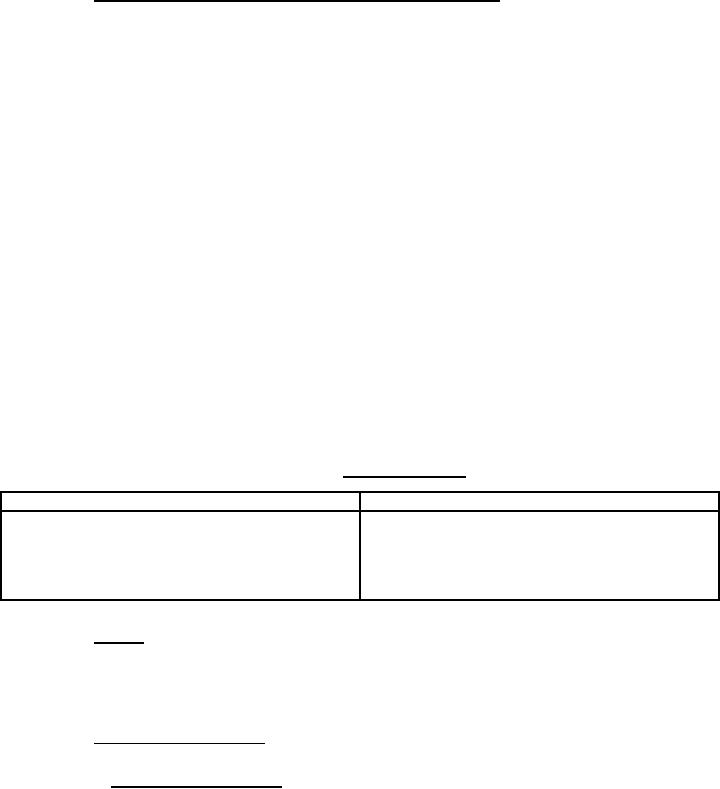

Force magnitude.

TABLE VI.

Nominal cable diameter (millimeters)

Compressive axial force (newtons)

10

0 to 2.9

20

3 to 5.9

50

6 to 9.9

100

10 to 19.9

200

20 and larger

4.7.2.8 Crush. Cable splices shall be tested in accordance with TIA/EIA-455-26,

with the exception that the test sample shall be a splice (see 3.5.8). The test load

shall be 1250 newtons, and the number of loads shall be one. Rubber pads shall not be

used on the two bearing surfaces. The change in optical transmittance shall be

measured during and after the test (see 4.7.3.2). At the completion of the test, the

splice shall be visually examined in accordance with 4.7.2.

4.7.2.9 Impact, cable splice. Cable splices shall be tested in accordance with

method A of EIA/TIA-455-2, moderate service class (see 3.5.9).

4.7.2.9.1 Impact, fiber splice. Fiber splices shall be tested in accordance with

method C of TIA/EIA-455-2. The change in optical transmittance shall be monitored

after the test in accordance with 4.7.3.2 (see 3.5.9).

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business