MIL-PRF-24623C

4.6.1.2.2 Failures. One or more failures shall constitute group A inspection

failure of the sample unit.

4.6.1.2.3 Disposition of sample units. Sample units that have failed any of the

group A inspection tests shall not be shipped or submitted for group B testing.

Qualification inspection.

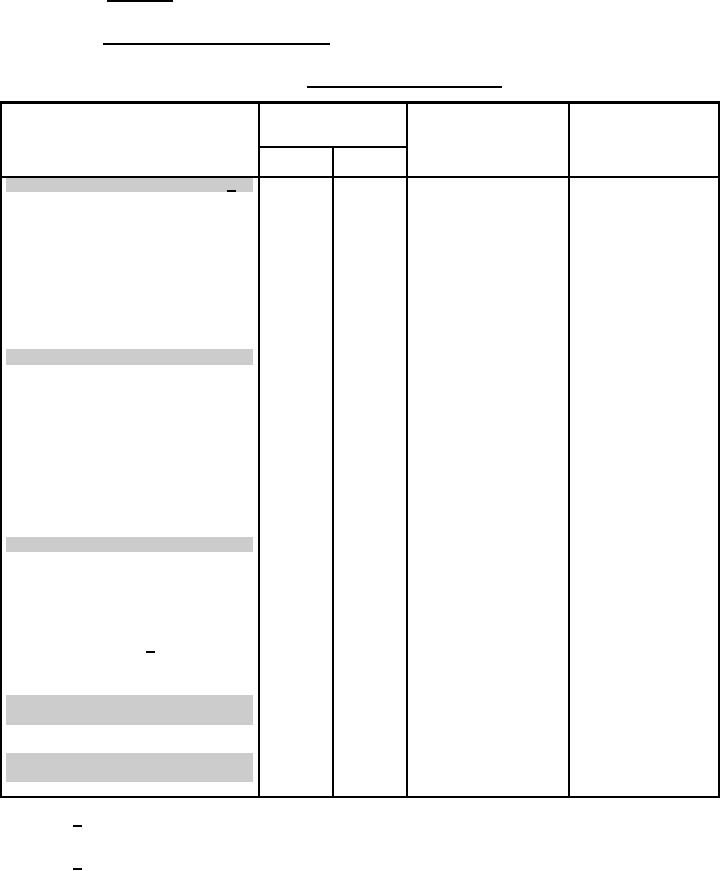

TABLE II.

Inspection

Application

Requirement

Test method

Paragraph

paragraph

Cable

Fiber

splice

splice

Group I (all sample units) 1/

Visual and mechanical

Size

X

3.5.1

X

4.7.2.1

Weight

X

X

3.5.2

4.7.2.2

Identification marking

X

X

3.5.4

4.7.2.4

Workmanship

X

X

3.8

4.8

Optical

Insertion loss

X

X

3.6.1

4.7.3.1

Return loss

X

X

3.6.3

4.7.3.3

Ambient light susceptibility

X

X

3.6.6

4.7.3.6

Crosstalk

X

3.6.5

4.7.3.5

Group II (2 sample units)

Cable pull out

X

3.5.13

4.7.2.13

Fiber pull out

X

3.5.12

4.7.2.12

Cable seal flexing

X

3.5.5

4.7.2.5

Twist

X

3.5.6

4.7.2.6

Impact

X

X

3.5.9

4.7.2.9

Crush

X

3.5.8

4.7.2.8

Axial compressive loading

X

3.5.7

4.7.2.7

Vibration

X

X

3.5.10

4.7.2.10

Mechanical shock

X

X

3.5.11

4.7.2.11

Water pressure

X

3.7.6

4.7.4.5

Salt spray

X

3.7.5

4.7.4.4

Group III (2 sample units)

Thermal shock

X

X

3.7.3

4.7.4.2

Temperature/humidity cycling

X

X

3.7.4

4.7.4.3

Temperature cycling

X

X

3.7.12

4.7.4.11

Life aging

X

X

3.7.2

4.7.4.1

Insertion loss

X

X

3.6.1

4.7.3.1

Freezing water immersion

X

3.7.7

4.7.4.6

Fluid immersion 2/

X

3.7.10

4.7.4.9

Sand and dust

X

3.7.8

4.7.4.7

Flammability

X

3.7.11

4.7.4.10

Group IV (lensed splices

only-2 sample units)

Nuclear radiation resistance

X

3.7.9

4.7.4.8

Group V (polymeric parts

only)

X

X

3.3.8

4.7.2.14

Fungus resistance

1/

Visual and mechanical tests listed in this group shall be performed on

unassembled splice parts. Assembled splices shall be used on the

remaining groups.

2/

Each sample unit shall be tested in all fluids.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business