MIL-PRF-29504B

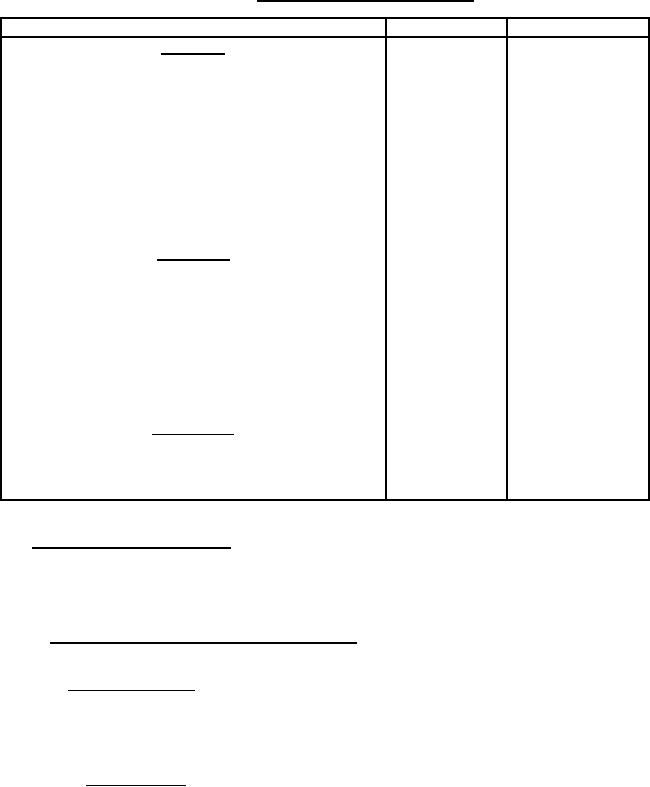

TABLE I.

Qualification inspection.

Inspection

Requirement

Test method

Group I

4.10

3.4.6

Interoperability

Visual

4.9.3

3.6.1

Size

4.9.4

3.6.2

Weight

4.9.5

3.6.3

Identification marking

-

Workmanship

3.8

Circular runout

3.6.5

4.9.7

Optical

Insertion loss

3.5.1

4.8.2

Return loss

3.5.3

4.8.4

Group II

3.6.9

Terminus insertion and removal forces

4.9.11

3.6.6

Terminus retention

4.9.8

3.6.7

Terminus engagement and separation force

4.9.9

3.6.13

Maintenance aging

4.9.15

3.6.10

Fiber pull out force

4.9.12

3.6.11

Cable pull out force

4.9.13

3.6.12

Mating durability

4.9.14

3.6.4

Terminus cleaning

4.9.6

Group III

3.6.8

Environmental/mechanical

4.9.10

3.3.5

Fungus resistance

4.9.16

4.7 Conformance inspection. Conformance inspection shall consist of the

inspection and optical tests specified for group A inspection (table II),

group B inspection (table III), and group C inspection (table IV).

Requirements for alternate forms of conformance inspection shall be as

identified in the qualification instructions (see 6.3.5).

4.7.1 Inspection of product for delivery. Inspection of product for

delivery shall consist of group A inspections.

4.7.1.1 Inspection lot. The inspection lot shall consist of termini

offered for inspection at one time, and all of the same design as covered by

one specification sheet and PIN. All of the termini in the inspection lot

submitted shall have been produced during the same production period with the

same materials and processes.

4.7.1.1.1 Sample unit. A sample unit shall be a terminus selected at

random from the inspection lot.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business