MIL-DTL-83522E

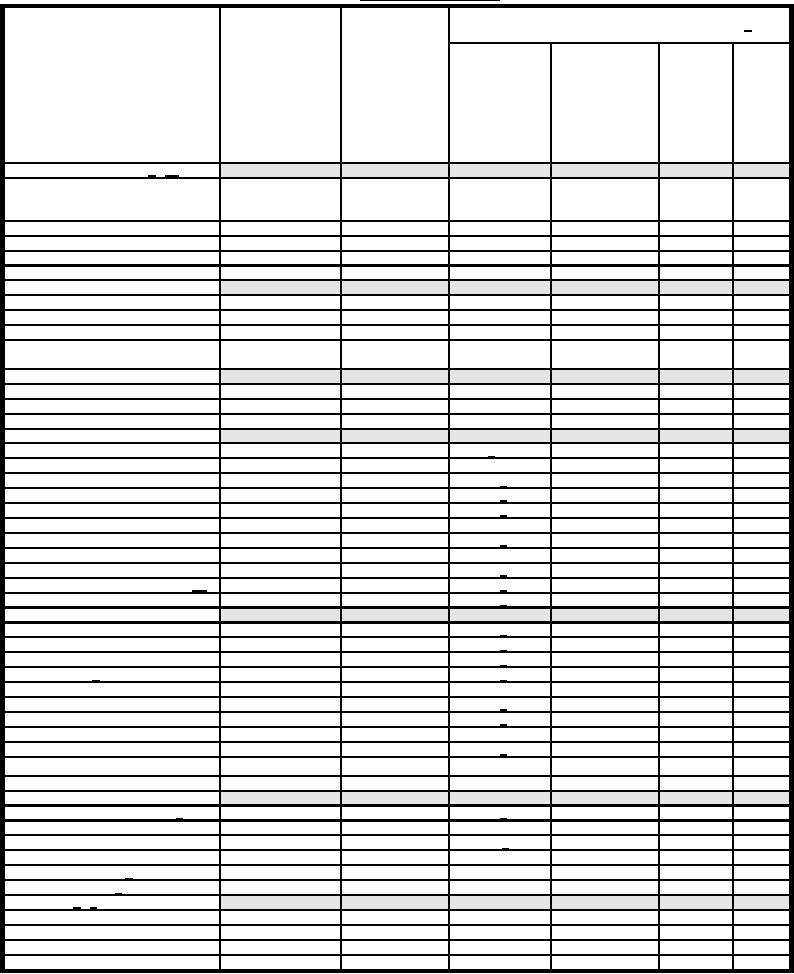

TABLE III. Qualification inspection.

Optical tests performed as part of the inspection 1/

Change in

Optical signal

Insertion

Return

optical

discontinuity

loss (see

loss

Inspection (test

transmittance

(see 4.7.9)

(see

Test

Requirements

methods)

(see 4.7.7)

performed

paragraph

paragraph

Group 1 (10 mated pair) 9/, 10/

Visual & mechanical

and 3.7

Size

Weight

Identification marking

Workmanship

Functional

Cable strain relief

Force to engage/disengage

Coupling proof torque

Coupling mechanical retention

force

Optical-8SM & 4MM mated pair

Insertion loss

X

Return loss-SM only

X

Ambient light susceptability

Group 2 (4 mated pair)

Tensile loading

X 3/ d&a

Cable strain relief

Flex life

X 3/

Twist

X 4/

Mating durability

X 3/

Return loss (SM only)

X

Impact

X 4/

Insertion loss verification

X

Vibration

X 4/

X

Mechanical shock-4SM & 4MM 11/

X 3/

X

Water submersion

X 3/

Group 3 (4 mated pair)

Thermal shock

X 4/

Temperature humidity cycling

X 3/

Temperature cycling

X 3/

Temperature 5/

X 3/

Temperature life

Return loss (SM only)

X 4/

X

Pressure altitude

X 3/

Insertion loss verification

X

Sand and dust

X 3/

Force to engage/disengage

Identification marking

Group 4 (2 mated pair & parts)

Nuclear radiation resistance 6/

X 3/

Fluid immersion (2 mated pair)

Salt spray (2 mated pair)

X4

Flammability (1 mated pair)

Fungus resistance 7/

Ozone exposure 7/

Group 5 2/, 8/

Thermal vacuum outgassing

4.9.1

Residual magnetism

4.9.2

Odor

Toxicity

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business