MIL-DTL-83522E

4.2.1 Responsibility for compliance. All items shall meet all requirements of sections 3 and 5. The inspection set forth in this

specification shall become a part of the contractor's overall inspection system or quality program. The absence of any inspection

requirements in the specification shall not relieve the contractor of the responsibility of ensuring that all products or supplies submitted

to the Government for acceptance comply with all requirements of the contract. Sampling inspections, as part of manufacturing

operations, is an acceptable practice to ascertain conformance to requirements, however, this does not authorize submission of known

defective material, either indicated or actual, nor does it commit the Government to accept defective material.

4.2.2 Test equipment and inspection facilities. Test and measuring equipment and inspection facilities of sufficient accuracy,

quality and quantity to permit performance of the required inspection shall be established and maintained by the contractor. The

establishment and maintenance of a calibration system to control the accuracy of the measuring and test equipment shall be in

accordance with ISO 10012.

4.2.3 Reliability assurance program. A reliability assurance program shall be established and maintained in accordance with MIL-

STD-790. Evidence of such compliance shall be verified by the qualifying activity of this specification as a prerequisite for qualification

and continued qualification.

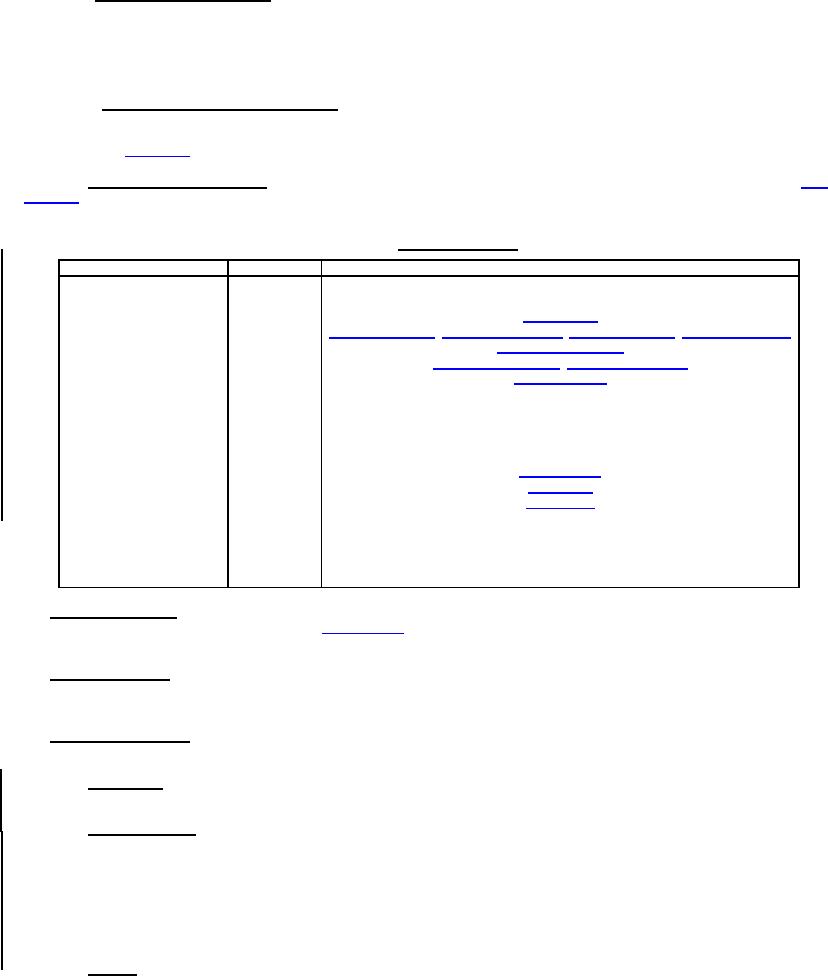

TABLE I. Materials inspection.

Component material

Requirement

Applicable specification paragraph

Metals

--

Zinc

--

ASTM - B86

Brass

--

Aluminum

--

Steel corrosion-resistant

--

Dissimilar metals

--

Bronze

--

--

Nonmetallic materials

TFE fluorocarbon

--

FEP fluorocarbon

--

Silicon rubber

--

Acetal

--

--

Adhesives (epoxies)

--

Sealing compounds

Lubricants

3.3.3.4

--

Liquid materials

4.3 Inspection conditions. Unless otherwise specified herein, all inspections shall be performed in accordance with the test conditions

specified in the "GENERAL REQUIREMENTS" of MIL-STD-202. For each test of threaded coupling connectors where the test is

performed on mated pairs, the pair shall be torqued to the specified value (see 3.1).

4.4 Materials inspection. Materials inspection shall consist of certification supported by verifying data that the materials listed in table I,

used in fabricating the connectors are in accordance with the applicable referenced specifications or requirements prior to such

fabrication.

4.5 Qualification inspection. Qualification inspection shall be performed at a laboratory acceptable to the Government (see 6.3) on

sample units produced with equipment and procedures normally used in production.

4.5.1 Sample size. Fourteen connector pairs of the same PIN with their appropriate adapters shall be subjected to qualification

inspection. Samples of all polymeric materials used in the construction of one mated connector pair is also required when applicable.

4.5.2 Inspection routine. The qualification table in this base specification, MIL-DTL-83522, lists the inspections cited in the base

specification with the sequence in with the inspections are to be performed. Inspections for qualification are tailored for each

component in the individual specification sheet (see 3.1). From the applicable qualification table (see 3.1), twelve mated connector

pairs shall be subjected to the specified inspections of test group I in table II. The twelve mated connector pairs shall then be divided

into three sets of four. Each set shall be subjected to the specified tests within one of groups II, III and IV of table II. Two additional

mated connector pairs shall be subjected to the flammability tests in group V of table II, when applicable. Samples of all polymeric

materials used in the construction of one mated connector pair shall be subjected to the fungus test of group V in table II, when

applicable.

4.5.3 Failures. One or more failures shall be cause for refusal to grant qualification approval.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business