MIL-DTL-83522E

4.5.4 Retention of qualification. To retain qualification, the contractor shall forward a report to the qualifying activity. Groups A

and B require a report at 2 year intervals, and group C requires a report at 5 year intervals. The qualifying activity shall establish the

initial reporting date. Retention of qualification shall be at a 5-year interval. The report shall consist of:

a. A summary of the results of the tests performed for inspection of product for delivery (groups A and B), indicating as a

minimum the number of lots that have passed and the number that have failed. The results of tests of all reworked lots shall be

identified and accounted for.

b. A summary of the results of tests performed for periodic inspection (group C), including the number and mode of failures.

The summary shall include results of all periodic inspection tests performed and completed during the 2 year or 5 year period. If

the summary of the test results indicates nonconformance with specification requirements, and corrective action acceptable to the

qualifying activity has not been taken, action may be taken to remove the failing product from the qualified products list. Failure to

submit the report within 60 days after the end of each 2 year or 5 year period may result in loss of qualification for the product. In

addition to the periodic submission of inspection data, the contractor shall immediately notify the qualifying activity at any time

during the 2 or 5 year period that the inspection data indicates failure of the qualified product to meet the requirements of this

specification. In the event that no production occurred during the reporting period, a report shall be submitted certifying that the

company still has the capabilities and facilities necessary to produce the item. If during 3 consecutive reporting periods there has

been no production, the manufacturer may be required, at the discretion of the qualifying activity, to submit a representative

product from each group, as defined in 4.5.2 to testing in accordance with the qualification inspection requirements.

4.5.5 Qualification by similarity. The extent of qualification testing by similarity shall be determined by the qualified products list

evaluating activity.

4.6 Quality conformance inspection.

4.6.1 Inspection of product for delivery. Inspection of product for delivery shall consist of groups A and B inspections.

4.6.1.1 Inspection lot. An inspection lot shall consist of all the connectors and associated fittings comprised of identical

piece parts produced under essentially the same conditions and offered for inspection at one time.

4.6.1.1.1 Group A inspection. Group A inspection shall consist of the inspections specified in table IV, and shall be made

on the same set of sample units, in the order shown.

4.6.1.1.1.1 Sampling plan. All products for delivery shall be subjected to group A inspections.

4.6.1.1.1.2 Rejected lots. If an inspection lot is rejected, the manufacturer may rework it to correct the defects, or screen

out the defective units ad resubmit for re-inspection. The manufacturer is not required to notify the qualifying activity of defective units

screened out during the group A inspections. Resubmitted lots shall be inspected using tightened inspection. Such lots shall be

separate from new lots and shall be clearly identified as re-inspected lots.

4.6.1.1.2 Group B inspection. Group B inspection shall consist of the inspections specified in table V in the order shown,

and shall be made on sample units which have been subjected to and passed the group A inspection. Connectors having identical

piece parts may be combined for lot purposes and shall be in proportion to the quantity of each part-numbered connector produced.

4.6.1.1.2.1 Sampling plan. The sampling plan for group B shall be in accordance with table II.

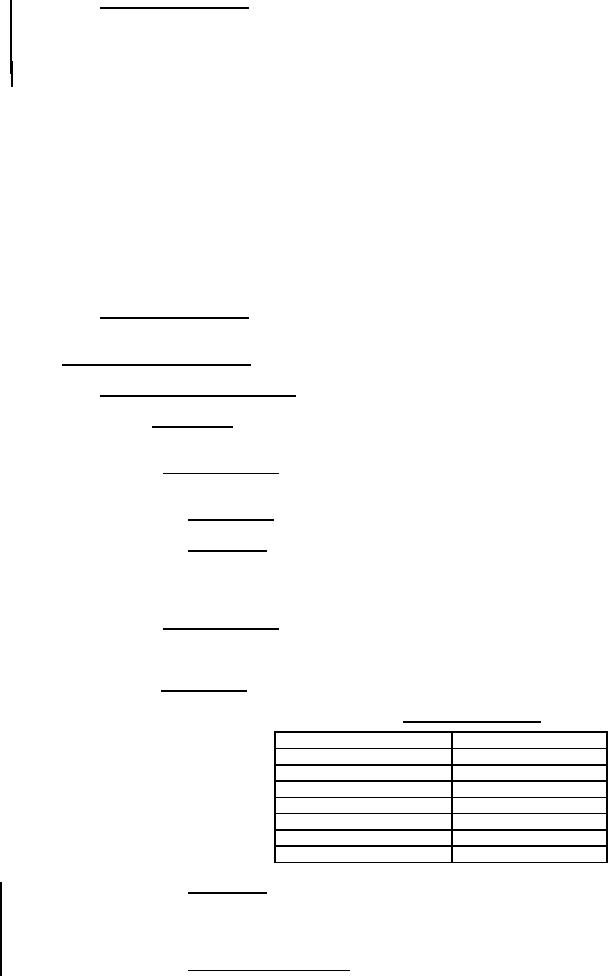

TABLE II. Group B sampling plan.

Lot size

Sample size

1-5

All

6-150

5

151-1,200

20

1201-10,000

32

10001-35000

50

35001-500000

80

500001 and over

125

4.6.1.1.2.2 Rejected lots. If an inspection lot is rejected, the manufacturer may rework it to correct the defects, or screen

out the defective units and resubmit for re-inspection. The manufacturer is not required to notify the qualifying activity of defective units

screened out during the group A inspections. Resubmitted lots shall be inspected using tightened inspection. Such lots shall be

separate from new lots and shall be clearly identified as re-inspected lots.

4.6.1.1.2.3 Disposition of sample units. Sample units which have passed all the group B inspection may be delivered on

the contract or purchase order, if the lot is accepted. Any connector or connector part deformed or otherwise damaged during testing

shall not be delivered on the contract or order.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business