MIL-DTL-83522/16C

NOTES:

1.

Dimensions are in millimeters.

2.

Inch equivalents are given for general information only.

3.

Use A (SM/MM) for single mode applications. Use A (SM/MM) or A (MM) for multimode applications.

4.

L dimensions is the diameter of a circle on the surface of the ferrule that is concentric with the axis of the

ferrule.

5.

Design optional.

6.

R dimension is for reference of conceptual design considerations only. This dimension is the radius of the

end of the ferrule when the surface of the ferrule is spherical, and L is as given.

7.

X dimension is the distance that the apex of the end of the ferrule extends beyond the circle described in

note 4.

8.

a angle to be between 20░ and 35░.

Part or Identifying Number (PIN) is a new term encompassing previous terms used in specifications such as

part number, type designator, or identification number and is as follows:

M83522/16

X

X

X

X

Configuration:

A (locking boot, long cap)

Configuration

D (nonlocking boot, either long or short cap)

E (protective cover)

F (90 degree boot, either long or short cap)

Temperature

Temperature:

H (high)

N (normal)

Fiber size

Fiber size:

X (type I) (125 Ám, MM)

Y (type II) (125 Ám, MM/SM)

Z (type I) (140 Ám, MM)

Additional

Additional consideration:

considerations

S qualified to space flight requirements

NOTE: Cap refers to the bayonet cap or ST connector outside metal housing. Barrel refers to interior metal part

that supports the ferrule and crimp sleeve.

REQUIREMENTS:

Metals: The plug housing and other metal components shall be of corrosion resistant steel in accordance with

SAE-QQ-S-763, class 303/316L or ASTM A-276, designation S31803, or nickel-plated brass, alloy 345 or 360,

in accordance with ASTM B-16/B16M.

Ferrule material: Ceramic (zirconia).

The dust cover, strain relief boot, and protective cap shall be made of thermoplastic or fluorosilicone.

Epoxies: Use an epoxy approved by the qualifying activity.

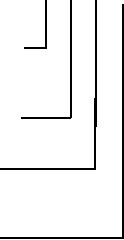

Dimensions and configuration: See figure 1.

Fiber optic cable requirements:

Cable configuration: In accordance with MIL-PRF-85045.

Fiber diameter: 50/125 Ám, 62.5/125 Ám, and 100/140 Ám, with the following respective tolerances:

125 ▒ 2 Ám (MM), 125 ▒ 1 Ám (MM/SM), 140 ▒ 2 Ám (MM).

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business