MIL-PRF-28876E

3.12.2 Insert retention axial strength. When tested in accordance with

4.6.4.2, connector inserts shall withstand an applied minimum pressure of 100

pounds per square inch (0.69 Mpa) in both the forward direction and the

backward direction for a minimum period of 1 minute without cracking,

breaking, or being dislocated from their normal positions in the connector

shell. No axial displacement detrimental to performance shall be observed

between the inserts and their shell body during or after the test exposure.

3.12.3 Terminus insertion and removal forces. Connectors shall be tested

in accordance with 4.6.4.3. The terminus insertion force and the force

required to remove unlocked termini shall not exceed 22.0 pounds (98 N).

3.12.4 Terminus retention force. When tested in accordance with 4.6.4.4

and subjected to axial loads of 22.0 pounds (98 N) termini shall be retained

in their inserts and axial displacements of the termini shall not exceed 0.015

inch (0.38 mm).

3.12.5 Maintenance aging. Connectors with removable termini shall be

tested in accordance with 4.6.4.5. Connectors shall show no visible evidence

of wear or deformation which may degrade their ability to perform as

specified. The terminus insertion and removal forces requirement of 22.0

pounds (98 N) (see 3.12.3) shall be met.

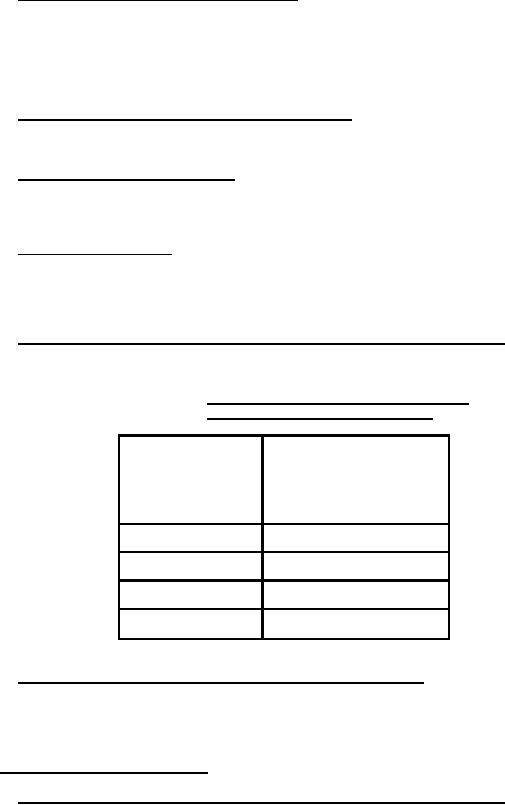

3.12.6 Connector coupling engagement and disengagement torque. When tested

in accordance with 4.6.4.6, the maximum coupling ring and coupling screw

engagement and disengagement torques shall be as specified in table III.

TABLE III.

Connector coupling engagement

and disengagement torques.

Connector coupling

Connector

shell size

engagement

and disengagement

torque (inch-

pounds (N-m))

11

15 (1.7)

13

15 (1.7)

15

25 (2.8)

23

50 (5.7)

3.12.7 Backshell and insert retention nut attachment. When tested in

accordance with 4.6.4.7, the minimum backshell or insert retention nut

disengagement torque shall be as specified in table III. No evidence of

excessive thread binding, seal pinching, or any contamination buildup shall be

observed.

3.13

Mechanical requirements

3.13.1 Cable pull out force (connectors with backshells only). When tested

in accordance with 4.6.5.1, the minimum cable to connector pullout strength

shall be 162 pounds (720.3 N). There shall be no evidence of cable jacket

damage, cable strain relief failure, cable to backshell seal damage,

distortion or bending of metallic connector parts, or cable disengagement from

the cable strain relief. The connector shall meet the requirements of 3.11.4

during and after the test.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business